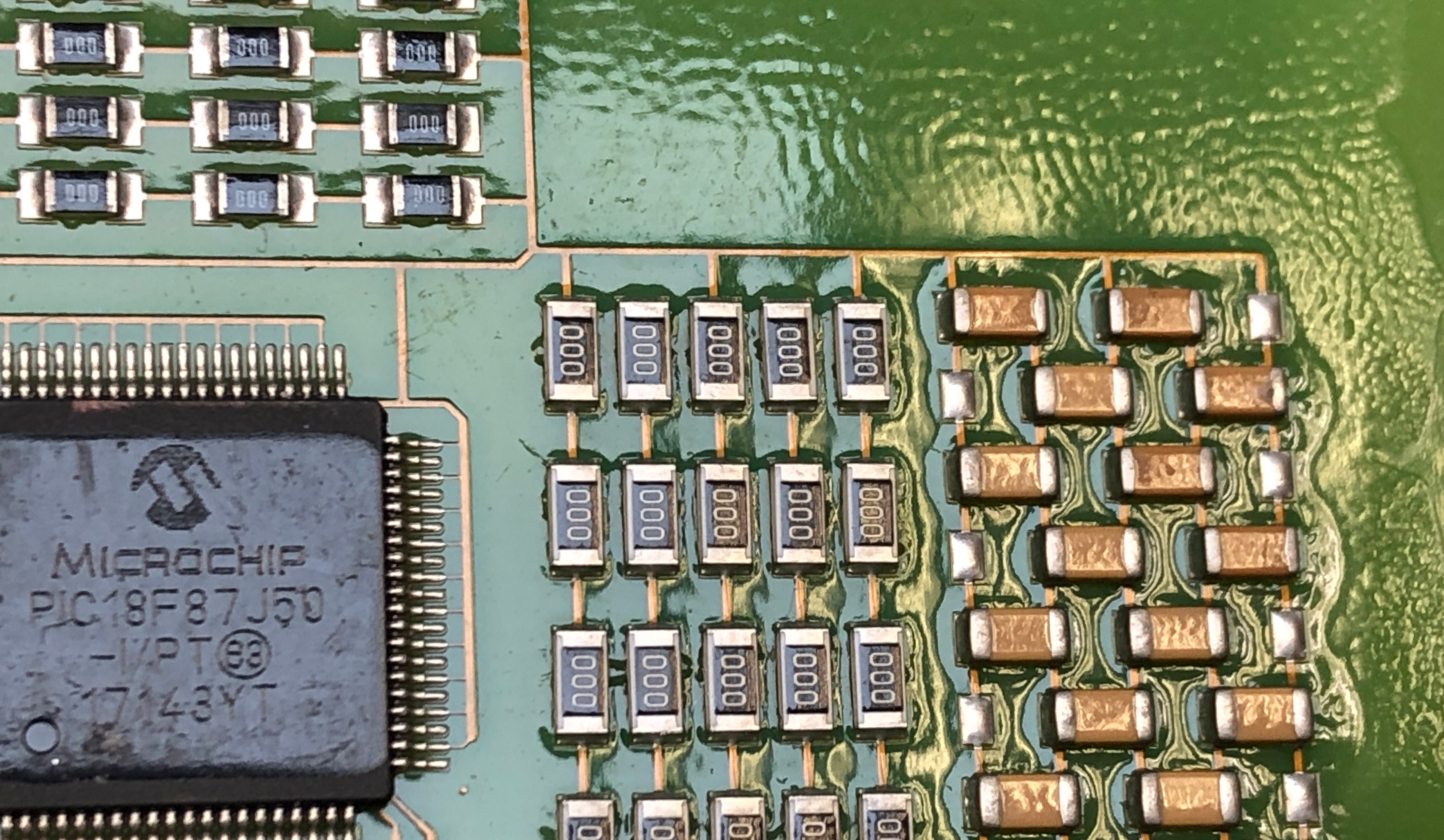

Conformal coating of printed circuit boards (PCBs) has resulted in a steady evolution in performance and protection for modern electronics. It has allowed for lightweight and reliable controls in industries such as automotive and aerospace among others. This has brought about the possibility of increased length of warranties as well as fewer failures and claims. Nevertheless, original equipment manufacturers (OEMs) and consumers continue to raise their standards and expectations for longevity and reliability to levels unimagined just 10 years ago. In the automotive industry, as an example, thermal cycling testing might have involved as few as 10 or 50 cycles in the recent past. That standard is now often 500 or even 1000 cycles with no apparent ending in sight.

So what do I do when conformal coating is not enough?