Conformal coatings offer tremendous protection to printed circuit board assemblies, but this assumes they properly adhere to the PCB. Application errors are all too common, causing delamination and otherwise poor adhesion of the material. So before producing at scale, you should routinely conduct adhesion tests to validate the integrity of your production processes.

Vlad David

Recent Posts

Explaining ASTM D3359: Adhesion Testing for Conformal Coatings

Topics: Epoxy Adhesives, adhesion test

Encapsulating for PCBs: How to Choose the Right Method

If you're familiar with HumiSeal through our blogs, you know we are big fans of conformal coatings. This is for good reason; with advancing conformal coating technology, innovative LED and UV curable coatings offer incredible protection for a large range of applications.

Conformal coatings are just one method of circuit board protection available to engineers. Those involved with PCBs may be familiar with the terms encapsulation. Encapsulation is a tremendously powerful method to secure and protect PCBs by submerging them in a protective material. In many cases, this is more desirable than selectively applying conformal coatings.

Topics: Encapsulants, Protection for PCB

Ruggedization of Electronic Circuits? Encapsulation is One of The Best-kept Protection Secrets

It's no secret that conformal coatings increase the lifetime of electronic devices by providing a thin barrier that strengthens their ability to withstand harsh environmental conditions. That said, a lesser-known truth is adhesives and encapsulants provide a significantly higher level of protection on the entire assembly.

Why is that? Well, adhesives and encapsulants promote assembly protection by:

- creating environmental seals that protect against moisture and corrosion

- providing high-temperature resistance

- increasing shock and vibration-dampening

- generating strong bonds to a variety of substrates

- maintaining low shrinkage

- offering thermal conductivity

Bury it in

Topics: Electronic Protection, Adhesive Solutions, Vibration Suppression, Encapsulants

Get the Best Results When Manual Brushing Conformal Coatings

Manual brushing is just one of many methods commonly used for applying conformal coating materials to PCBs and other components. It is a hand-applied method that requires little investment into automation or equipment. With practice, it can be one of the simplest methods available, especially for small-batch production or isolated applications.

Topics: Conformal Coatings, conformal coating application, Manual Brush

Complete Guide to Viscosity Part 2: Measurements and Devices Explained

This blog is the second installment in our two-part series on viscosity (with special consideration on adhesives and coatings).

In our previous viscosity blog, we discussed the properties of viscosity and how viscosity can be affected by temperature, the addition of dilution or thinning agents, and other similar factors.

Topics: conformal coating, viscosity

This is the first in a short series on material viscosity, in which we will review what it is and how to measure it. We will start with the definition of viscosity. Viscosity is the internal friction of moving fluid and a measurement of the resistance of a fluid deformed by shear stress. It is measured in centiPoise. The lower the number, the less viscous the material, as can be seen by this comparison chart: starting with water at 1 cPs and ending with honey at anywhere between 2,000 – 10,000 cPs.

Topics: conformal coating, Coating Application Preparation, conformal coating application, viscosity, Humiseal Blog

Improve Precision and Reduce Time When Removing Conformal Coatings

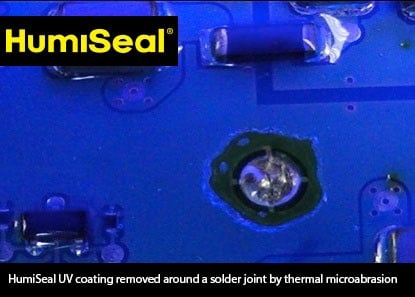

UV curable conformal coating materials such as HumiSeal UV40 are frequently used in military, aerospace and automotive applications due to superior resistance to chemicals and mechanical stress. These properties make them difficult to remove when rework under the coating is required.

There are products available for chemical removal of conformal coatings, but many are restricted by government regulation and health and safety concerns.

An effective method for localised removal of conformal coatings, allowing the rework of the components, is the powder or micro-abrasion equipment.

Topics: Micro Abrasion, conformal coating application, conformal coating removal

A Quick Guide to Understand IPC-CC-830B Qualification Standard

IPC CC-830 revision B is a conformal coating qualification standard mostly used by board fabricators, OEM design engineers, and coatings suppliers.

There are two fundamental uses of this IPC standard:

- Coatings’ performance capabilities

- Quality consistency

In this blog, we will go over some of the specifications along with tests requirements, passing criteria, and quality characteristics.

Topics: Conformal Coatings, Conformal Coating Process, Standard Qualifications, IPC-CC-830B

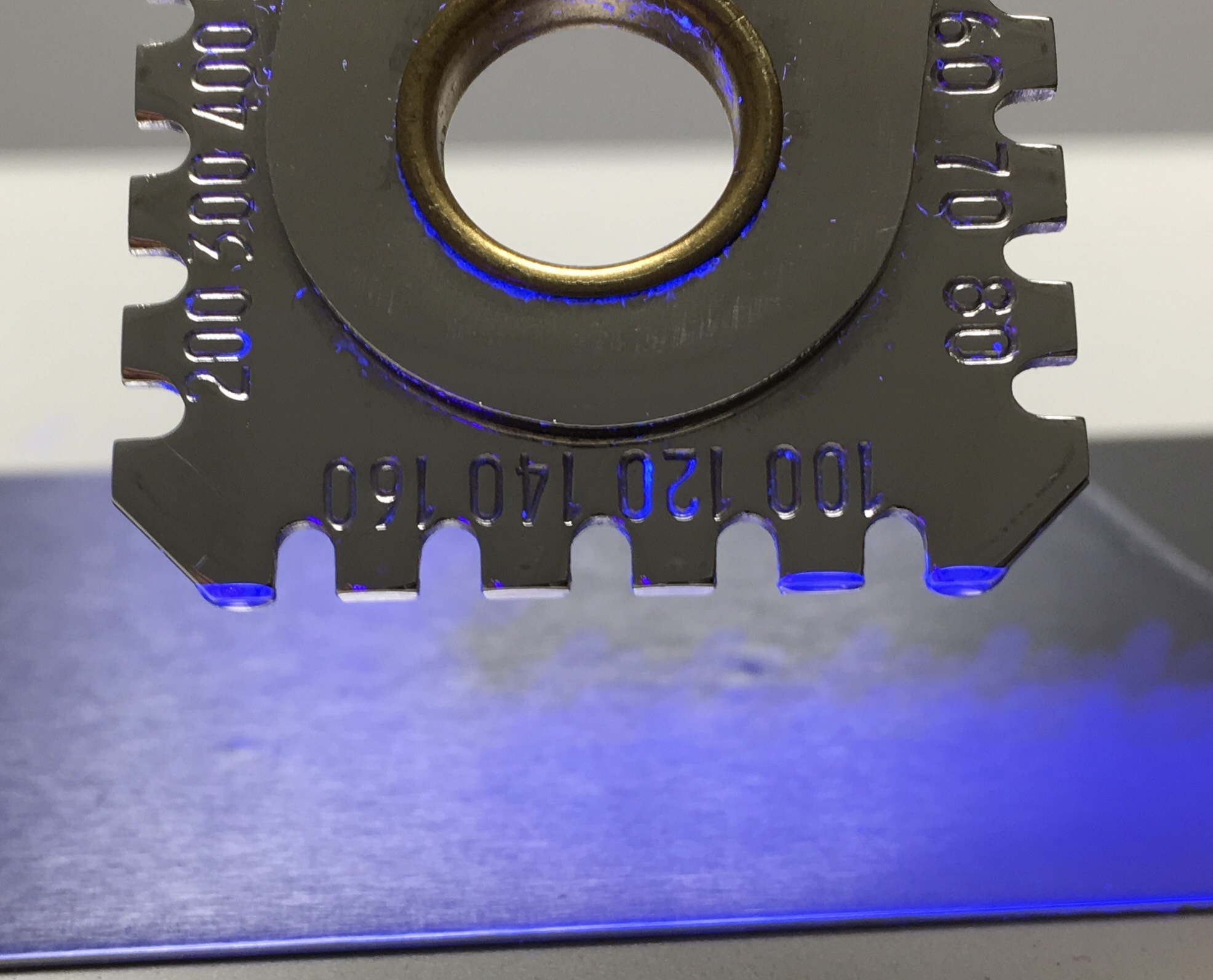

What is a Wet Gauge and How to Measure Conformal Coating Thickness?

The application of the conformal coating in a uniform and consistent coverage is a key challenge that defines the reliability of the finished product.

A thin coating will provide inadequate protection against corrosion or insulation between conductors. Conversely, if the conformal coating is too thick, it will increase the risk of forming other types of coating defects such as bubbles, insufficient curing, and potential cracking during thermal shock cycles.

Besides the verification of the process parameters such as coating viscosity and the application method is correctly setup, the amount of conformal coating material applied on the printed circuit boards can be measured before curing. For this, wet film conformal coating thickness gauges are used. This method ensures quality control while the coating material is still wet.

Topics: Conformal Coatings, Coating Application Preparation, Conformal Coating Process