Picking a Conformal Coating

You and your organization have spent weeks or months researching conformal coatings to meet the demanding specifications of your customers. These can include factors such as dielectric strength, thermal and mechanical shock properties, processing considerations, and so on. At some point, the critical consideration of price and cost must be added to the equation. The amalgamation of cost and performance could be considered a measure of the true value of any specific coating.

A key factor for understanding is that:

price ≠ cost

The design goal for conformal coatings would essentially consist of identifying the lowest cost coating on a dry solids basis that can comfortably meet specifications and process effectively.

The What and Why of Solids Percentage

It is a basic but commonly overlooked factor that plays into an evaluation of coatings costs: solids percentage. Conformal coatings, like nearly all coatings and adhesives, come in a wide range of solids percentages. In an ideal world, all coatings would be supplied as 100% solids with no additives or carrier materials that are not integral parts of the final coating.

Historically, however, coatings and adhesives are supplied at far less than 100% solids for a couple of reasons:

- viscosity reduction for ease of processing (spraying, dipping, roll coating…)

- ease of processing through the use of wetting or adhesion-promoting additives

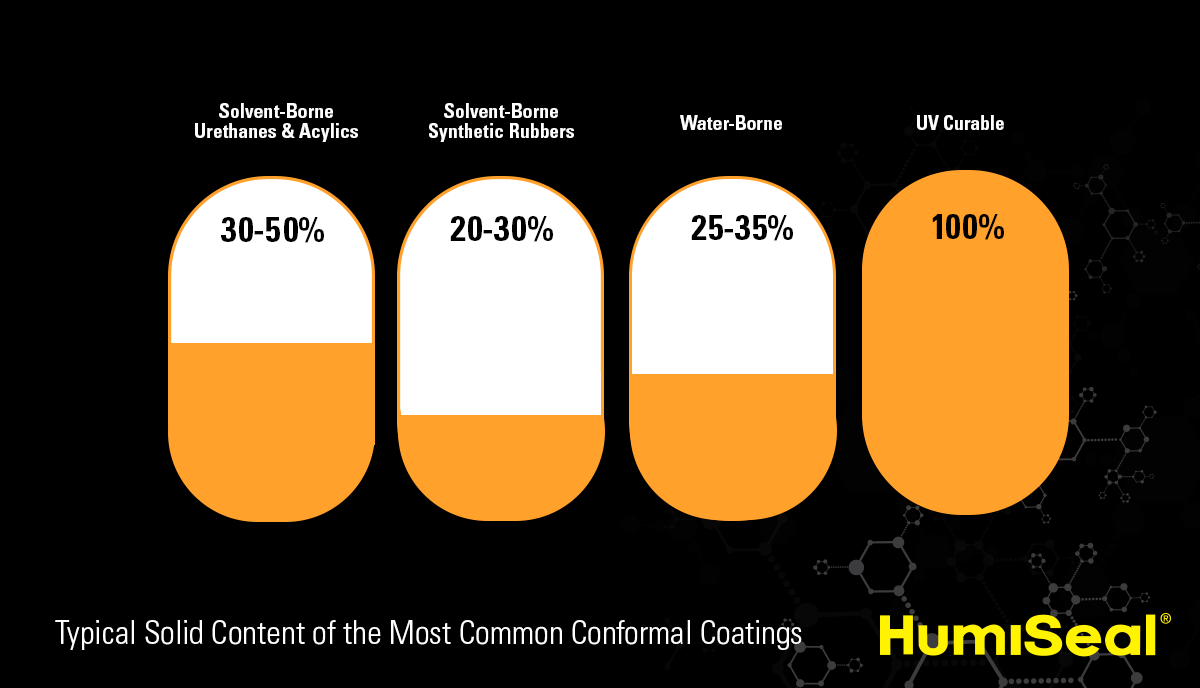

Typical Solid Content of the Most Common Conformal Coatings

Does Solids Percentage Affect My PCB?

In many respects, the answer to this question is that, all other things being equal, the percentage solids of 2 equivalent products should not affect the protection of your PCB. There are some fairly complex processing and manufacturing considerations that will be affected at times by solids and viscosity, but once the ancillary additives and solvents are dried and processed, the finished coating properties will remain very much the same.

It seems like common sense, but it is commonly overlooked that often as much as 75% (or more) of your conformal coating is additives. These additives, such as viscosity-reducing solvents or wetting agents, are often critical to your manufacturing process, but in fact have little or nothing to do with the finished properties of your conformal coating or the PCB to which they are applied.

So How Do I Really Compare Costs and Assess Value?

In order to correctly assess cost vs. value, your organization needs to understand that:

- the lowest price coating is not necessarily the lowest cost, and

- a comparison of coating prices by volume or weight cannot be undertaken until the solids percentages of the coatings are added to the calculation.

One of the newer and most efficient technologies in conformal coatings is UV curable technology. As can be seen in the graphic above, the coating is supplied at 100% solids. This coating was developed to eliminate the need for viscosity-reducing solvents as processing aids. The coating’s unique chemistry consists of a thin liquid polymer that is hardened or cured nearly instantly with exposure to UV light. The coating is often accompanied by an eye-popping price in the minds of purchasing agents, but in fact can represent a great value when solids percentages are considered.

Let’s examine a representative example:

Chemistry “Price” Actual Cost/Solid Liter

Solvent-borne synthetic rubber $X per liter at 25% solids X/.25 = $4X

Solvent-borne urethane $1.1X/liter at 40% solids 1.1X/.40= $2.75X

UV curable $2X/liter at 100% solids 2X/1.0= $2X

The above example emphasizes the point that the solids percentage of a conformal coating can be the most important factor to be considered when assessing value. In this case, the highest price material, which is the UV curable chemistry at 2 times the solvent borne price, is in fact the most cost-efficient material when solids are considered. Of course, there are many other considerations that may be issues, including existing application equipment, cycle times, environmental health and safety considerations, and others.

As a supplier of all major forms and chemistries of conformal coatings, Chase and HumiSeal® can help you with an unbiased approach to evaluating your application and process. We’ll show you how to maximize efficiency, minimize cost, and improve product reliability. Our outstanding manufacturing and technical support groups can provide your organization with reliable global supply, unmatched quality, and superior technical support.

Please contact us today to discuss your application