Packaging. Not the most complex subject when choosing a conformal coating, but treat the decision too lightly at your peril. There are a surprising number of options available, each suitable to very specific needs and conditions. In this brief presentation we will discuss, from smallest to largest, the various packaging choices available to you, along with the advantages and disadvantages of each.

Conformal Coating Packaging Options: We Can Help You Decide

Topics: conformal coating, Conformal Coating Process, Conformal Coating Packaging

How to Make Sure That Your Conformal Coating Actually Conforms

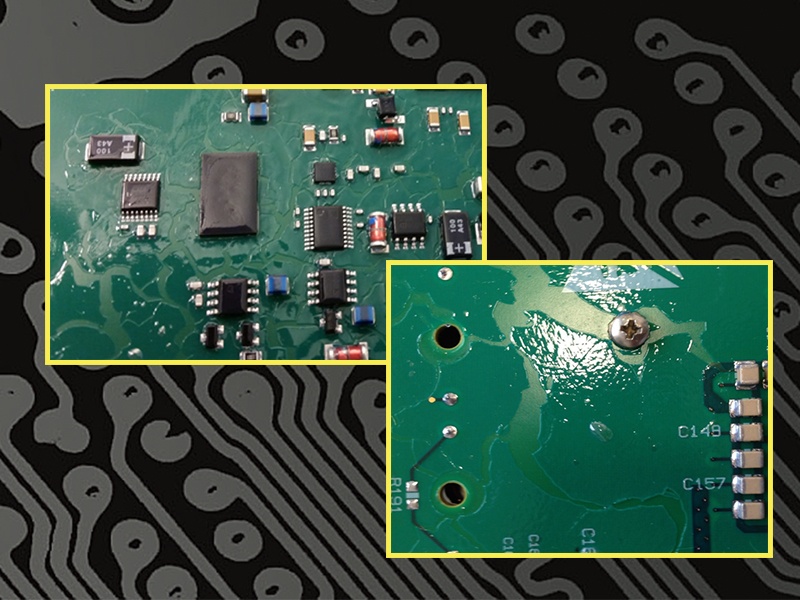

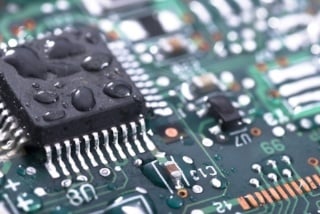

Take a quick look at the photograph on your right. If you are in the business of PCB manufacturing with conformal coatings, does it frighten or concern you at all? Does the magnified coating appear to truly “conform” to the surfaces evenly? And if not, what effect, if any, might this have on the protection of your PCBs?

First of all, don’t panic. What you see in the photograph is not unusual and is not necessarily a problem. It is important, however, that if you are in the business of applying conformal coatings, you should have a clear understanding of some of the unique challenges they present.

Topics: conformal coating, silicone conformal coating, Humiseal, Conformal Coating Process

Advantages & Characteristics of LED Curable Conformal Coatings

UV curable conformal coatings have attained widespread use in applications requiring fast through-put times, such as automotive, white goods, and industrial control manufacturing. In addition to speed of cure, UV curable conformal coatings provide the advantage of high physical protection and chemical resistance for electronic systems. Traditionally the UV curing of coatings is an energy intensive process. One that uses high-power mercury discharge lamps, which as a result of use produce considerable amounts of heat and ozone. The recent introduction of new, high-output LED UVA light units allows for the successful cure of conformal coatings by using between 365nm and 395nm wavelength of UVA light, effectively curing with minimal heat and no ozone generation.

Topics: UV Curable (Type AR/UR), Conformal Coating Process, conformal coating application, UV Curing, UV light, UVA

Understanding the Importance of the Moisture Vapor Transmission Rate of Conformal Coatings

A critical function of conformal coatings is to protect PCBs and electronics from damage caused by moisture and humidity. In this discussion, we will attempt to answer some of the more common questions we often hear regarding the level of protection you can expect from a conformal coating.

Are conformal coatings waterproof?

The above is probably the most common question and most misunderstood subject in the area of PCB protection

Topics: Environmental Conditions, Conformal Coating Process, Conformal coating benefits, waterproofing silicones, waterproofing

Conformal Coating Quality + Reputation = Reliability for Your PCB

The electronics industry is exploding with the introduction of innumerable consumer devices designed with ever more complex functions and controls. These range from the relatively mundane such as controlling the temperature in your home to potentially life-saving including deploying airbags in your car or sensing hazardous road conditions. The demand for smarter and more complex electronics is becoming more important in everyday life.

Topics: Conformal Coating Process, conformal coating application, Conformal coating benefits

Optimizing Conformal Coating Flow Rates to Save Time and Money

In a previous blog “How to Save Time and Money by Measuring the Right Amount of Viscosity,” viscosity was described as critical to the conformal coating process. This post will cover some of the technical details related to coating flow rate and the significant potential for savings of both time and money for PCB manufacturers.

Topics: Conformal Coating Process, conformal coating application, Humiseal Blog, Flow rates

A Quick Guide to Understand IPC-CC-830B Qualification Standard

IPC CC-830 revision B is a conformal coating qualification standard mostly used by board fabricators, OEM design engineers, and coatings suppliers.

There are two fundamental uses of this IPC standard:

- Coatings’ performance capabilities

- Quality consistency

In this blog, we will go over some of the specifications along with tests requirements, passing criteria, and quality characteristics.

Topics: Conformal Coatings, Conformal Coating Process, Standard Qualifications, IPC-CC-830B

Simple Steps to Ensure Proper Wetting & Good Adhesion

Have you ever seen your conformal coating separate or de-wet? Have you observed the conformal coating to flake off after cure? The key to your success is understanding the relationship between surface energy (of the substrate) and surface tension (of the conformal coating). There are some simple steps you can take to help ensure you possess a healthy balance of both.

Topics: Humiseal, Conformal Coating Process, proper wetting, troubleshooting, surface energy, conformal coating application

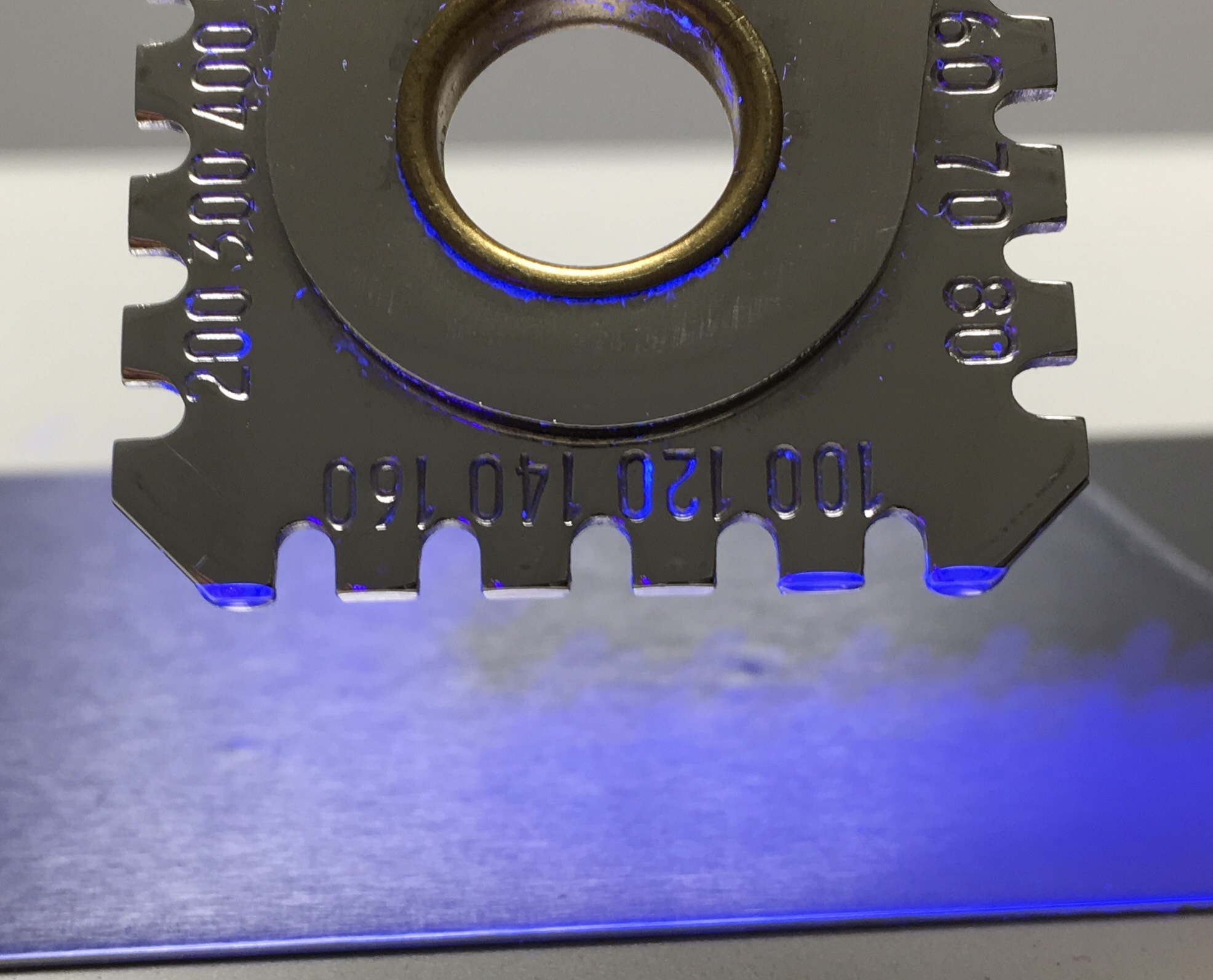

What is a Wet Gauge and How to Measure Conformal Coating Thickness?

The application of the conformal coating in a uniform and consistent coverage is a key challenge that defines the reliability of the finished product.

A thin coating will provide inadequate protection against corrosion or insulation between conductors. Conversely, if the conformal coating is too thick, it will increase the risk of forming other types of coating defects such as bubbles, insufficient curing, and potential cracking during thermal shock cycles.

Besides the verification of the process parameters such as coating viscosity and the application method is correctly setup, the amount of conformal coating material applied on the printed circuit boards can be measured before curing. For this, wet film conformal coating thickness gauges are used. This method ensures quality control while the coating material is still wet.

Topics: Conformal Coatings, Coating Application Preparation, Conformal Coating Process

Straightforward Explanation of the MIL-I-46058C Specification for Conformal Coatings

During your selection of conformal coating you ran in to a specification that you have seen before but not fully understood, MIL-I-46058C. Conformal coating choices are vast, but with so many available, how does a user pick the correct one? Are there minimum standards that define what a conformal coating is supposed to do? Thankfully, yes there are. This article will focus on one such standard: MIL-I-46058C.

The official title for the specification is MIL-I-46058C, Insulating Compound (For Coating Printed Circuit Assemblies). The standard serves as a material standard, used to evaluate and document that a particular coating meets a list of specific performance attributes (more on those later). The MIL-I-46058C was developed to define a uniform set of test methods and performance requirements for conformal coatings and gives users confidence that the material they select will perform.

Topics: Conformal Coatings, Conformal Coating Process, Mil-I-46058