It's no secret that conformal coatings increase the lifetime of electronic devices by providing a thin barrier that strengthens their ability to withstand harsh environmental conditions. That said, a lesser-known truth is adhesives and encapsulants provide a significantly higher level of protection on the entire assembly.

Why is that? Well, adhesives and encapsulants promote assembly protection by:

- creating environmental seals that protect against moisture and corrosion

- providing high-temperature resistance

- increasing shock and vibration-dampening

- generating strong bonds to a variety of substrates

- maintaining low shrinkage

- offering thermal conductivity

Bury it in

When Should You Use Adhesives and Encapsulants on your PCB

HumiSeal adhesives and encapsulants are available as 1K or 2K compounds with medium to high viscosity. They can be used in the following processes:

Bonding and Staking

Used for the purpose of joining or securing a component in order to increase shock and vibration resistance by releasing the strain from the solder joints.

Staking: Like shoving a stake in the ground. The stakes provide mechanical support to other components in the PCB. It typically involves things that are taller (batteries or capacitors) that require additional support. The polymer acts as a support to the PCB.

Bonding: The process of bonding (sticking together) multiple components. Staking does not require bonding, but in some cases, it may. (Delete bonding references)

Related Article: How Best to Protect PCB Mounted Components from Vibration

Potting or Casting

Involves a case filled with liquid potting material to completely cover the device and the components. In casting, a temporary frame is used.

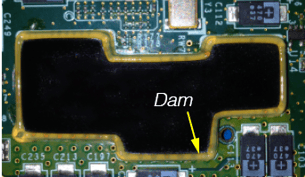

Potting: Burying something in a polymer to protect it. Some potting applications use a frame or a box to encase the material. In instances where this frame is absent, you may with to create a dam to outline the required section.

Related Article: 5 Simple Steps to Eliminate Bubbles in Potting Encapsulants

Encapsulation: Dam and Fill

Utilized to enclose, without the use of a case or frame, small areas of the assembly to address critical components that require a high level of protection.

Fully immersing an object (in our case, PCB) within a protective coating to increase its durability.

|

|

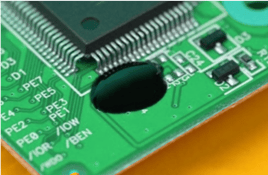

Glob top: dabbing a chunk of viscose materials which effectively bubbles over the delicate components.

4 of the Best Methods for Encapsulation Applications on a PCB

The following offers a wide range of application methods, such as

1) Manual application with dispensing guns

Advantages

- easy access in tight areas

- quick change of syringe, mixer, and needle

Disadvantages

- operator dependent

- poor control of the dispensed quantity

2) Semi-automated dispensing systems

advantages

- easy access in tight areas

- quick change of syringe, mixer, and needle

- good control of the quantity dispensed

- pressure regulator and time-dispensing control

disadvantage

- operator dependent

Related Article: 4 Tips to Successfully Apply Two-Component Epoxy Adhesives

3) Automated benchtop robots

advantages

- programmable

- superior control of the dispensed quantity

- high throughput

- adaptive for 1- and 2-part syringes or bulk

disadvantages

- limited working area

- cannot be integrated into a conveyorized inline process

4) Fully-automated dispensing systems

advantages

- PC-integrated software for programming

- progressive pumps and vacuum control available for accurate bubble-free dispensing

- configurable for 1- and 2-part syringes or bulk

- bigger working area

- weight check and needle calibration

- conveyorized integration with existing inline process

disadvantage

- high cost

HumiSeal’s wide range of adhesives and encapsulants allows you to increase the level of protection of the entire assembly or specific components, regardless of the application method chosen.

If you have questions, you can always contact us.