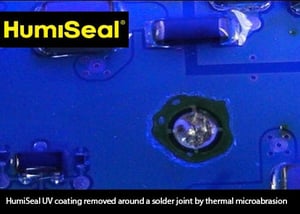

UV curable conformal coating materials such as HumiSeal UV40 are frequently used in military, aerospace and automotive applications due to superior resistance to chemicals and mechanical stress. These properties make them difficult to remove when rework under the coating is required.

UV curable conformal coating materials such as HumiSeal UV40 are frequently used in military, aerospace and automotive applications due to superior resistance to chemicals and mechanical stress. These properties make them difficult to remove when rework under the coating is required.

There are products available for chemical removal of conformal coatings, but many are restricted by government regulation and health and safety concerns.

An effective method for localised removal of conformal coatings, allowing the rework of the components, is the powder or micro-abrasion equipment.

How does it work?

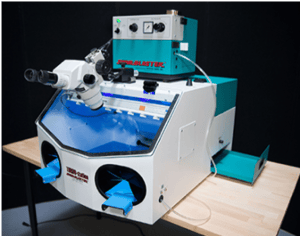

Figure - Powder Abrasion Equipment

This method uses very fine particles of wheat starch, allowing conformal coatings to be safely and selectively removed. The wheat starch powder, being relatively soft, removes the conformal coating from around components and solder joints without damaging the component markings or the solder resist surface. The equipment is fully ESD safe using static dispersive methods at the powder application tip and in the general work area.

This method uses very fine particles of wheat starch, allowing conformal coatings to be safely and selectively removed. The wheat starch powder, being relatively soft, removes the conformal coating from around components and solder joints without damaging the component markings or the solder resist surface. The equipment is fully ESD safe using static dispersive methods at the powder application tip and in the general work area.

The powder abrasion system has adjustable powder flow control and air pressure regulation to enable removal of a wide range of conformal coatings from the hardest to the softest. All HumiSeal conformal coatings can be removed by this method.

The key factors to ensure an effective coating removal are:

- air pressure;

- powder flow rate, which is the ratio of abrasive powder to air flow volume;

- nozzle diameter;

- distance of the nozzle from the work piece; and

- duration of the process application – feed rate.

The desktop unit is self-contained, requiring only manpower and compressed air to function. It has internal powder collection with built-in filtration.

Watch how Powder Abrasion System works:

Why should I use this removal method?

The main benefits of using the microabrasion method for localised coating removal consist of high precision and reduced time required.

|

|

|

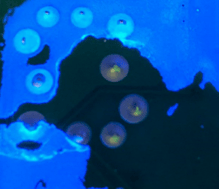

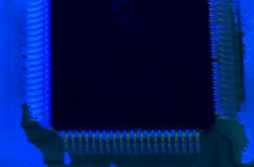

Figure - Examples of localised coating removal |

|

Microabrasion of conformal coatings is the modern way of removing coatings without using hazardous chemicals, and it provides a safe and clean environment for operators. HumiSeal has worked with Crystal Mark on microabrasion of conformal coatings for a number of years and recommends this method of removal.

Contact us if you want to learn more about conformal coatings removal. We are always happy to assist you.