Conformal coatings offer tremendous protection to printed circuit board assemblies, but this assumes they properly adhere to the PCB. Application errors are all too common, causing delamination and otherwise poor adhesion of the material. So before producing at scale, you should routinely conduct adhesion tests to validate the integrity of your production processes.

Explaining ASTM D3359: Adhesion Testing for Conformal Coatings

Topics: Epoxy Adhesives, adhesion test

This blog post outlines the techniques required for the removal of HumiSeal UV cure conformal coating. The products covered in this article are:

- UV40, UV40-250

- UV50LV

- UV500, UV500LV

Topics: Conformal Coatings, Humiseal, Micro Abrasion, conformal coating removal

HumiSeal® has been manufacturing its products in Pune, India for over eight years.Duringthistime we have significantly invested in our site--including manufacturing equipment, quality test equipment, and staff.

Our facility is now unmatched in its level of manufacturing equipment, technology, and product quality. Although the factory primarily supports the Indian market, it will also join our other manufacturing sites around the World to deliver manufacturing redundancy to our wider customer base around the globe as and when required.

Topics: Humiseal

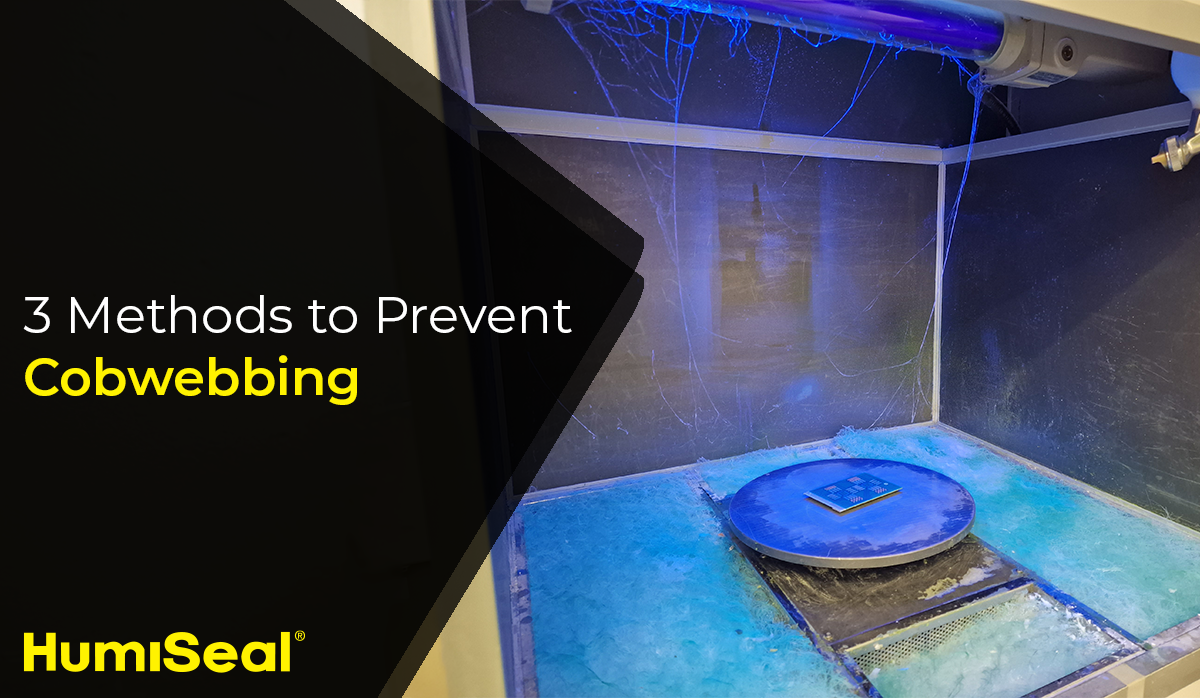

Conformal coating is generally the last step in the PCB manufacturing process and the method of protection for all those valuable functional components, but it's not always that simple. Let's look at a fairly common scenario.

Everything was moving along fine through the design and testing process. You have begun production spraying and suddenly there are wisps of translucent webs floating in the air. Your taller components look like a scene from the movie Arachnophobia. This is the oft-dreaded cobwebbing effect; and while it may appear confounding and a little scary, it is often one of the simplest problems to eliminate when conformal coating.

In this brief article, we will discuss the likely causes of this odd situation and provide some simple solutions to get you back to applying your coating in a defect-free manner. Let's begin by exploring the phenomena in more detail.

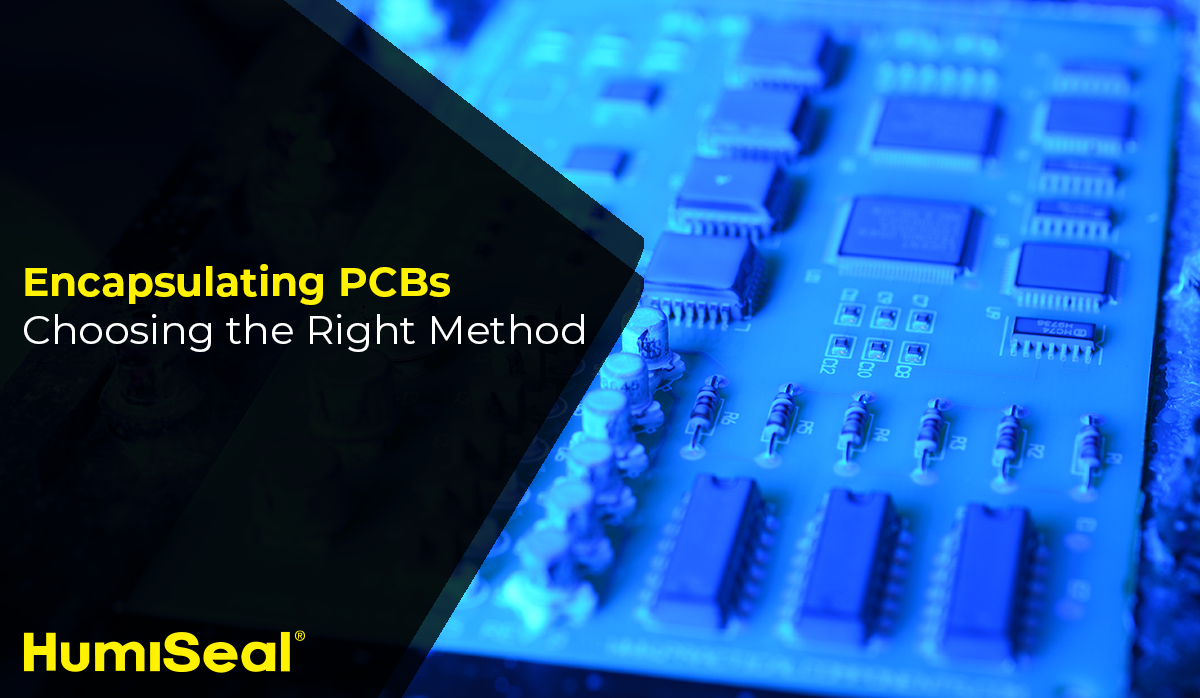

Encapsulating for PCBs: How to Choose the Right Method

If you're familiar with HumiSeal through our blogs, you know we are big fans of conformal coatings. This is for good reason; with advancing conformal coating technology, innovative LED and UV curable coatings offer incredible protection for a large range of applications.

Conformal coatings are just one method of circuit board protection available to engineers. Those involved with PCBs may be familiar with the terms encapsulation. Encapsulation is a tremendously powerful method to secure and protect PCBs by submerging them in a protective material. In many cases, this is more desirable than selectively applying conformal coatings.

Topics: Encapsulants, Protection for PCB

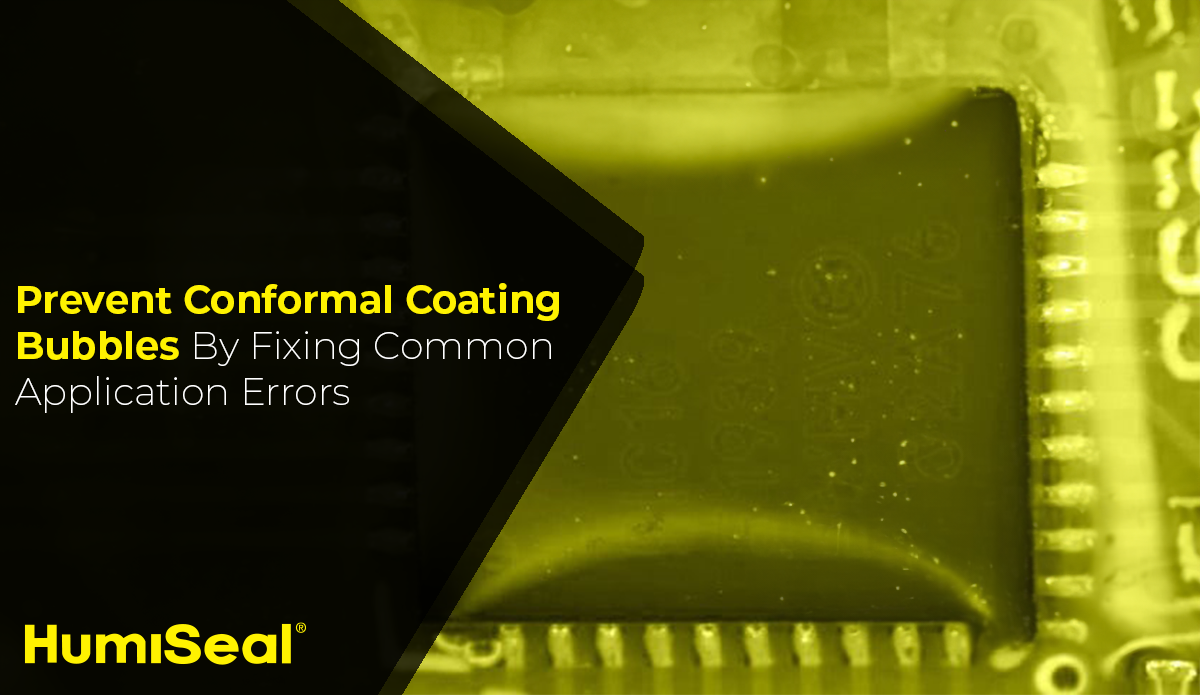

Prevent Conformal Coating Bubbles by Fixing Common Application Errors

Bubbles. They can be a real challenge in any adhesive or coating, but they are particularly undesirable when covering electronics and printed circuit boards (PCBs) with fluid conformal coating material. The technical support engineers at Humiseal have over five decades of experience in support of PCB manufacturers. They report that bubbles within the finished film are the most commonly reported technical issue they receive.

In this brief article, we will discuss many of the causes as well as many potential solutions to the problem of entrapped bubbles.

Topics: Conformal Coating Troubleshooting, bubbles

Toluene-Free Conformal Coatings: Alternatives to Aromatics

Toluene and Xylene: solvents that have shown value and utility within the adhesives and coatings industries for decades. However, they often serve as a double-edged sword, offering superior solvent and drying capabilities but accompanied by some negative health and environmental impacts.

Topics: Aromatic Free, toluene

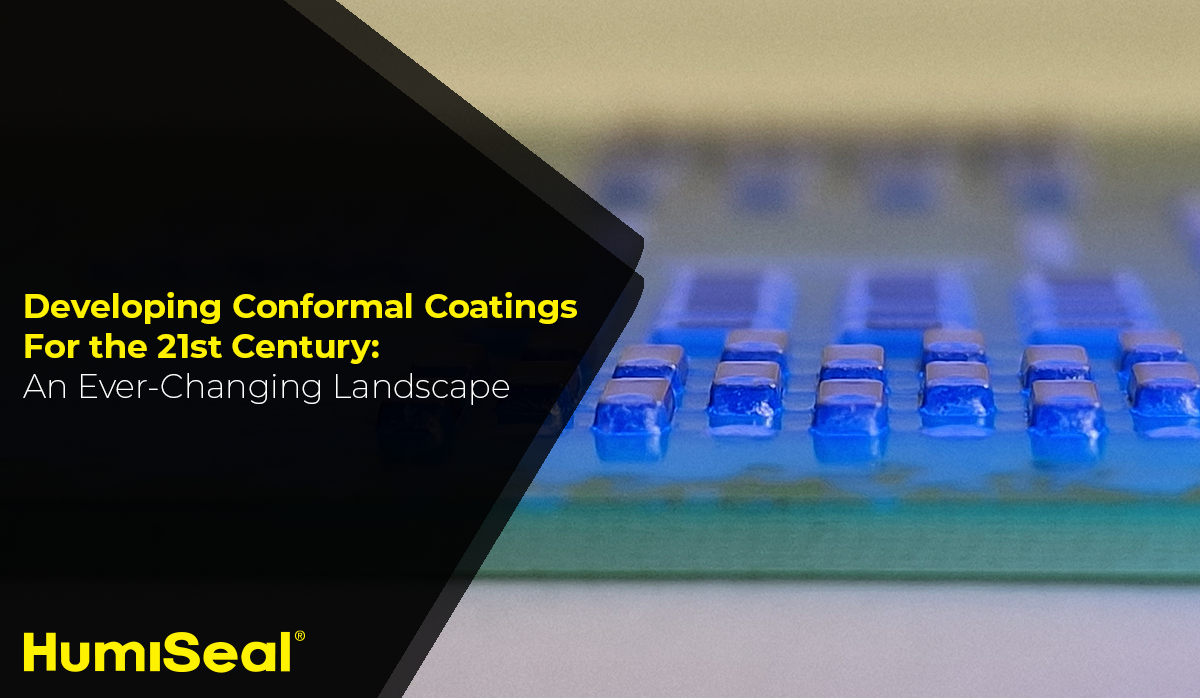

Developing Conformal Coatings for the 21st Century: An Ever-Changing Landscape

Before we look at conformal coating in the 21st Century, it is worth looking at how our industry has changed since the 20th Century and the effect these changes have had on reliability.

30 years ago, we had:

- Through-hole PCAs with axial components and wide conductor spacing (see fig. 1)

- Round axial components that were easy to conformably coat

- Wide conductor spacing (causing a few problems with dendritic growth)

- Leaded solder

- The widely adopted practice of cleaning before conformal coating

Fig. 1

Now move forward 30 years. In that time, surface mount components have been developed that are predominantly square with sharp edges, conductor spacing has been reduced, and packing densities have increased to levels never dreamt of in the past (see fig. 2).

Topics: Conformal Coatings, Sharp Edge

Tired of Masking Conformal Coating Applications? Try Selective Dip Coating Instead

When conventional coating methods such as hand spray, total dipping or robotic selective coating don’t provide the protection required, there is always selective dip coating.

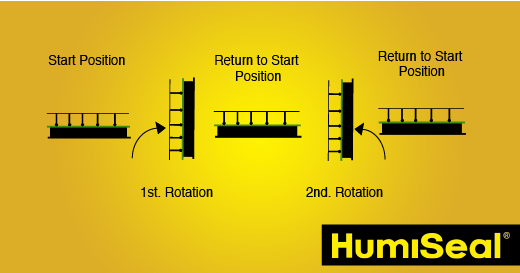

What is selective dip conformal coating?

Selective dip coating is a process whereby the substrate rather than globally immerised in the coating, is discreetly coated in desired locales. The technique in one form or another, has been around for over 25 years and is used with both classic solvent-based coatings and 100% UV cure conformal coatings.

Topics: Conformal Coatings, Humiseal, Selective Dip Coating, Electronic Protection

Ruggedization of Electronic Circuits? Encapsulation is One of The Best-kept Protection Secrets

It's no secret that conformal coatings increase the lifetime of electronic devices by providing a thin barrier that strengthens their ability to withstand harsh environmental conditions. That said, a lesser-known truth is adhesives and encapsulants provide a significantly higher level of protection on the entire assembly.

Why is that? Well, adhesives and encapsulants promote assembly protection by:

- creating environmental seals that protect against moisture and corrosion

- providing high-temperature resistance

- increasing shock and vibration-dampening

- generating strong bonds to a variety of substrates

- maintaining low shrinkage

- offering thermal conductivity

Bury it in

Topics: Electronic Protection, Adhesive Solutions, Vibration Suppression, Encapsulants