Coating Dense, Modern PCBs with Sharp Edge Coverage (SEC)

In 2022, HumiSeal started the development of a new classification of materials to meet the needs of today's surface mount components: Sharp Edge Coverage.

What is Sharp Edge Coverage?

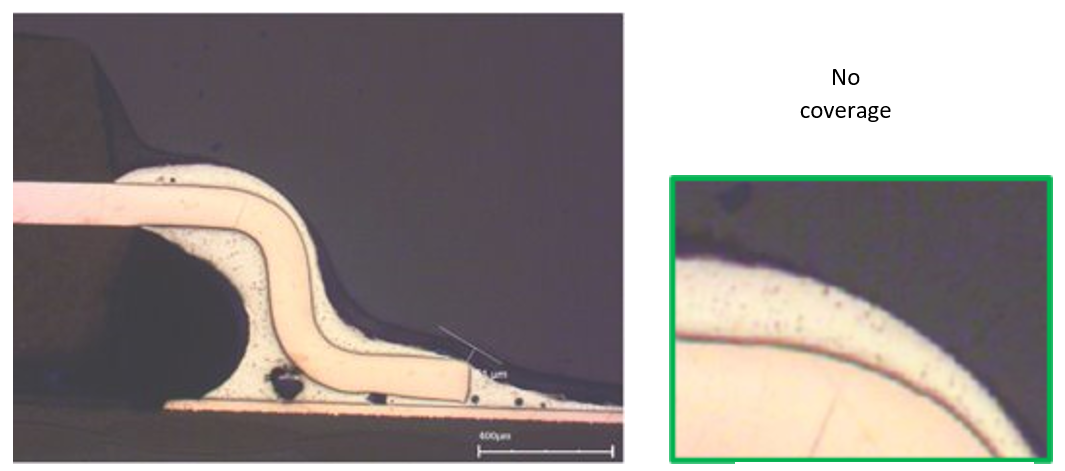

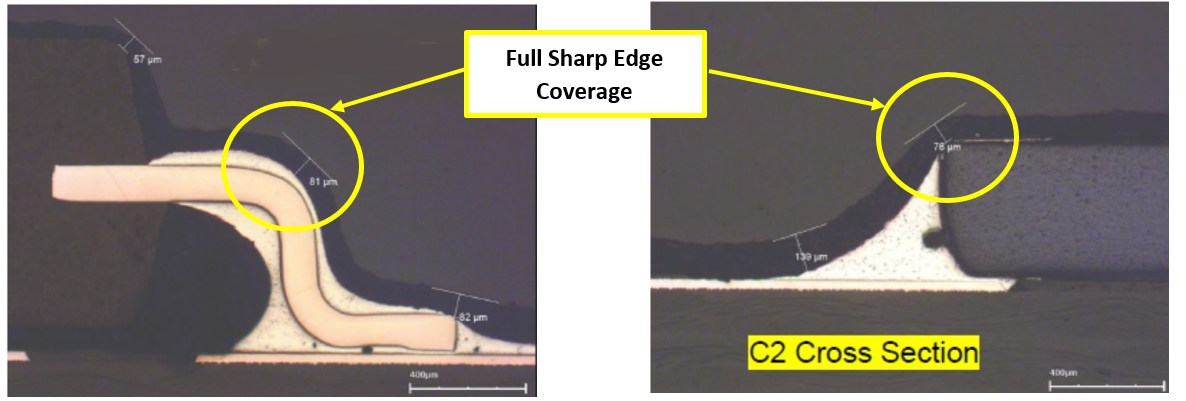

Poor or no coverage of conformal coating on the sharp edges of surface mount components leads to a range of potential failures that include electro-migration on the surface of coatings, system failure due to condensation across the surface of the PCA, and potential unrestricted growth of tin whiskers. Traditionally, SEC has been addressed by applying multiple coating layers, this can be a time-consuming process and costly.

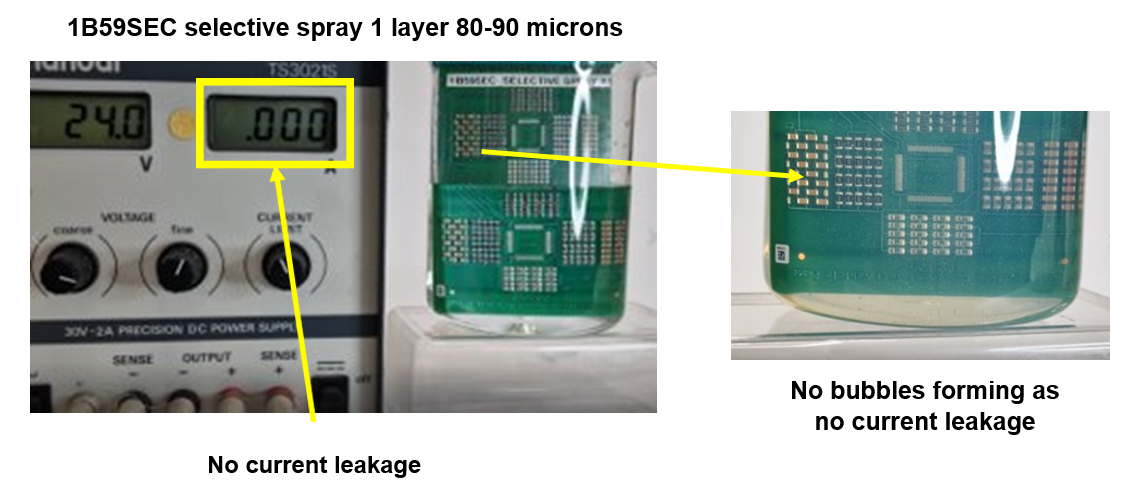

HumiSeal had initially developed two products to address this problem: 1B59SEC and 1A33SEC. A single 80um layer of 1B59SEC has been shown to be more effective than two or more 40um layers of a conventional coating (see fig. 4 & 5).

Fig. 4

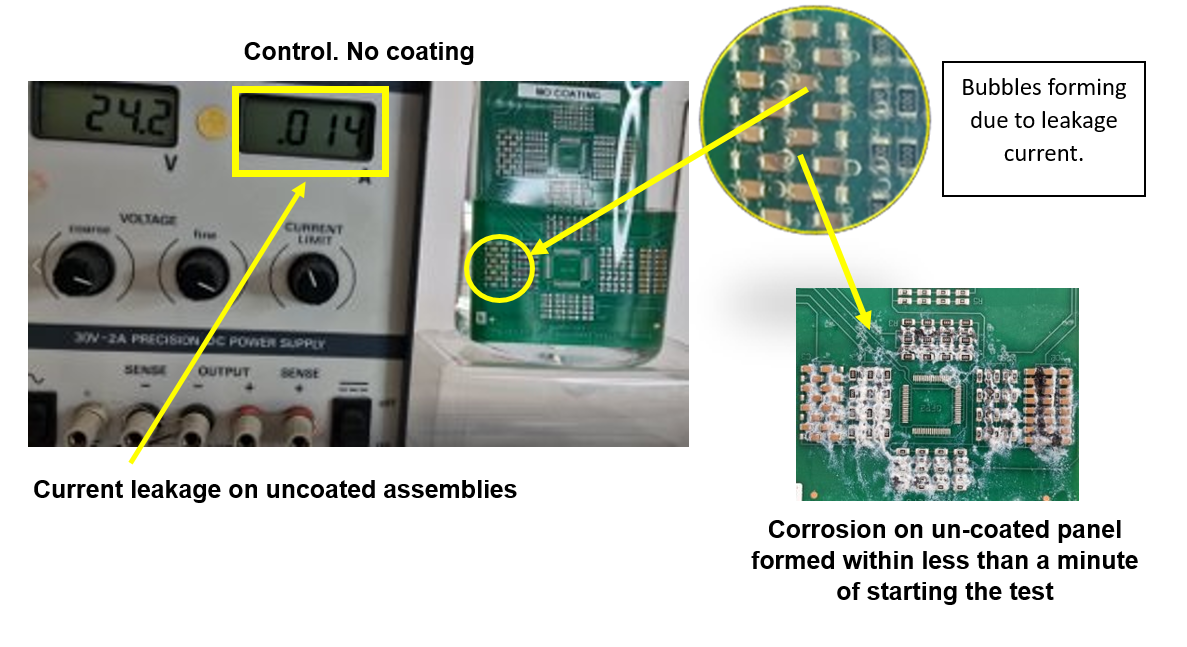

The SEC products can be applied in a single layer, that gives full protection to the PCA, including Sharp Edges of the surface mount components. To confirm that the new SEC coating gives the protection envisaged an immersion test was developed by the HumiSeal R&D laboratory. This test consisted of a beaker of salt water, equivalent to seawater, a 24-volt power supply, and test boards designed for SIR evaluation and condensation testing.

Fig. 5

So, How Did We Test?

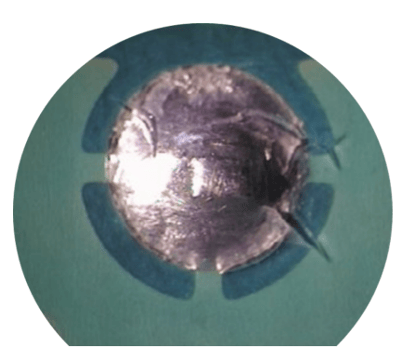

Two test boards were used one coated with a single layer of 1B59SEC at 80µm and one without coating; in turn, they were connected to the power supply, and 24 volts were applied to the onboard circuit and then immersed in the salt water. Figure 6 shows the uncoated board under test, please note the leakage current flowing, the bubbling taking place around the components, and the final corrosion on the board.

Fig. 6

Figure 7 shows the test board coated with 1B59 SEC under test, note the zero leakage current and no bubbles forming around the components. This development by HumiSeal will provide superior protection for printed circuit boards operating in high humidity and harsh environments, providing long-term reliability.

Fig. 7

As a supplier of all major forms and chemistries of conformal coatings, Chase Corporation and HumiSeal® can help you with an unbiased approach to evaluating your application and process. We’ll show you how to maximize efficiency, minimize cost, and improve product reliability. Our outstanding manufacturing and technical support groups can provide your organization with reliable global supply, unmatched quality, and superior technical support.

Please contact us today to discuss your application.

Fig. 1

Fig. 1 Fig. 2

Fig. 2 Fig. 3

Fig. 3