For decades, Chase Corporation and our Humiseal brand have been the originators and recognized leaders in PCB protection with conformal coatings. Humiseal also provides products and technical support for a complete line of encapsulants. While conformal coatings provide adequate protection in most instances, sometimes you just need a little more coverage! Humiseal encapsulants add a whole new level of protection against extreme temperature and chemical exposure.

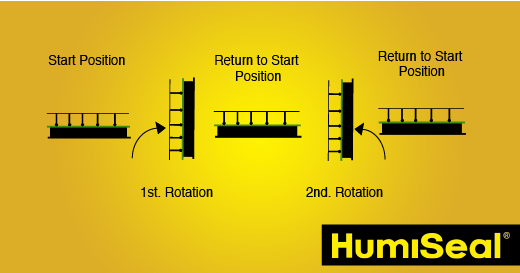

So, if you currently use Humiseal conformal coatings, there are certain industry-established methods, both manual and automated, for applying them. This usually involves either spraying them, manually hand brushing conformal coatings, or dipping the entire board. Encapsulants are quite different and the following are some common application methods with pros and cons to help in your decisions.