In previous articles, we discussed common defects in conformal coatings related to surface energy issues. These included issues such as

In previous articles, we discussed common defects in conformal coatings related to surface energy issues. These included issues such as

- fish eyes

- lack of coating coverage

- poor bonding

- delamination

We received significant feedback, and the most common response was to ask for more specifics about just what surface energy is anyway.

Surface Energy versus Surface Tension

Surface chemistry is an enormously complex and cussed branch of the sciences; consequently, we will attempt only a layman's discussion and understanding here. For the purposes of conformal coating, surface energy must be considered for both the exposed surface of the PCB as well as for the coating itself.

Commonly when talking about solids, the term SURFACE ENERGY is used, while when considering liquids or coatings, the term SURFACE TENSION is used instead.

Surface Energy of Solids

Surface energy of solids is usually expressed in units of dynes per centimeter, or most often dynes for short. The surface energy of a given solid is a characteristic of its chemistry and surface topography. In the case of printed circuit boards and conformal coating, the surface that we are trying to wet-out and bond-to is usually the solder mask or in some cases, component surfaces.

Related article:Simple Steps to Resolve Conformal Coating Wetting Problems

Here is a basic chart for surface energy, or dynes (chart right), of some common solids (chart left). In general, higher numbers mean easier to coat evenly without surface defects.

| Surface of Liquids | Tension |

| Aluminum | 1000 |

| Glass | 300 |

|

Epoxy (solder mask) |

45 |

| PVC | 39 |

| Polyethylene | 31 |

| PTFE | 18 |

Surface tension of liquids is also usually expressed in dynes. All pure liquids have a pretty reliable and measurable surface tension at set conditions. Water for example has a very high energy at about 73 dynes, while standard industrial solvents (e.g.,toluene and xylene) used in conformal coatings are much lower at about 28 dynes.

Below is a basic chart for surface energy, or dynes (chart right), of some common liquids (chart left). In general, lower numbers mean easier to coat evenly without surface defects.

| Common Liquids | Tension |

| Water | 73 |

| Ethylene | 48 |

| Xylene | 29 |

| Toluene | 28 |

| MEK | 25 |

| Cyclohexane | 25 |

| Isopropanol (IPA) | 23 |

What Does the Term “Wetting” Mean?

In PCB manufacture and conformal coating, you are likely to encounter the term “wetting”. For those unfamiliar, this is simply a less than scientific terminology to describe whether a liquid or coating “wets” a given surface.

A conformal coating has good wetting or wets out a PCB surface if the coating flows and forms a continuous, defect free, consistent thickness liquid film. Conversely a coating that beads up, forms defects such as fish eyes, or forms a film with gaps or variations in thickness has bad wetting or does not wet out adequately.

|

|

| Good wetting | Bad wetting |

Related articleSimple Steps to Ensure Proper Wetting & Good Adhesion

A Real World Example of Surface Energy

A simple real world example to help in understanding surface energy and wetting to which many can relate is the process of waxing a car. The metal or painted surface of your car is quite high in surface energy and will if uncoated “wet out” water and rain droplets along with dirt to a uniform film. To avoid this, we coat our cars with a very low energy coating such as waxes and fluoropolymers. The result is that we have lowered the energy of our car surface which causes rain and dirt droplets to bead up and fall away more easily. The process of waxing your car is essentially the opposite of what we would want to see to get proper wetting and bonding with conformal coatings.

Surface Energy Solid > Surface Tension Liquid Coating= Good Adhesion/Wetting

The factors affecting surface energy are many and beyond our scope, but for the purposes of most coating operations including conformal coating the important thing to remember is that the measured surface energy of your solid (PCB surface) must be higher than the surface tension of the conformal coating to get proper wetting and adhesion.

A basic illustration of this can be seen in the below graphics. On the left is a solder mask surface(green) with surface energy that exceeds that of the conformal coating (yellow) resulting in proper and uniform wetting. On the right are 2 examples where the solid surface energy is below that of the coating resulting in poor wetting and beading. The more extreme the difference in energy, the more pronounced the de-wetting or beading can be. This is often measured by measuring the contact angle of the bead.

%20with%20surface%20energy%20that%20exceeds%20that%20of%20the%20conformal%20coating%20(yellow)%20resulting%20in%20proper%20and%20uniform%20wetting.jpg?width=1200&name=solder%20mask%20surface(green)%20with%20surface%20energy%20that%20exceeds%20that%20of%20the%20conformal%20coating%20(yellow)%20resulting%20in%20proper%20and%20uniform%20wetting.jpg)

As a supplier of electronics protection polymers and coatings, Chase Corporation and our employees can help you with an unbiased approach to evaluating your application and process. We’ll show you how to maximize efficiency, minimize cost, and improve product reliability. Our outstanding manufacturing and technical support groups can provide your organization with reliable global supply, unmatched quality, and superior technical support.

How Do I Measure Surface Energy of My PCB?

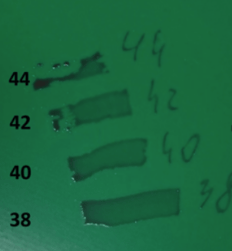

The most common method of surface energy measurement is a simple comparative test by using dyne pens. Dyne pens contain a variety of solutions with predetermined surface tension characteristics. In this test the unknown surface energy is referenced by the known surface tension of applied solution and is expressed as dynes/cm. Good wetting of the solution is ensured when surface energy of the substrate is equal to or higher than the surface tension of applied test liquid. Please reference Dyne pen manufacturer’s procedure for proper use. A basic illustration is shown below. In this example, the surface shows inhibited wetting between the 40 line and the 42 line meaning the surface has an energy of approximately 40 to 41 dynes/cm.

The most common method of surface energy measurement is a simple comparative test by using dyne pens. Dyne pens contain a variety of solutions with predetermined surface tension characteristics. In this test the unknown surface energy is referenced by the known surface tension of applied solution and is expressed as dynes/cm. Good wetting of the solution is ensured when surface energy of the substrate is equal to or higher than the surface tension of applied test liquid. Please reference Dyne pen manufacturer’s procedure for proper use. A basic illustration is shown below. In this example, the surface shows inhibited wetting between the 40 line and the 42 line meaning the surface has an energy of approximately 40 to 41 dynes/cm.

Surface Energy Guidelines

In general, HumiSeal recommends a minimum surface energy of 38 dynes or more measured immediately preceding the conformal coating station.

Unfortunately, there are many processes prior to conformal coating that will cause a reduction in the surface energy of a PCB. Most of these conditions are caused by the deposition or migration of low surface energy contaminants to the PCB such as oils, waxes, or plasticizing agents. Some sources can include:

• Handling during inspection or assembly processes

• Plasticizer migration from reflow of other heat processes

• Inadequate heat profile during reflow, flux residues

• Use of incompatible cleaning fluids and agents

• Contamination from packaging or storage media

Simple handling, transportation, and reflow process all add ionic and non-ionic contaminants. Develop stage-gate surface energy checks between each step in the SMT process to determine where the surface energy is affected. Once identified, put in proper corrective actions to address the source of any type of contaminants.

Please contact us today to discuss your application.