Most anyone over the age of 30 has probably seen Back to the Future and remembers Marty McFly. One line of Marty’s that inexorably drew him into ill-advised actions was the classic “Nobody calls me yellow.” Nothing good comes from yellow, and this turns out to be just as applicable in LCD screen manufacture as it was in the movie.

Most anyone over the age of 30 has probably seen Back to the Future and remembers Marty McFly. One line of Marty’s that inexorably drew him into ill-advised actions was the classic “Nobody calls me yellow.” Nothing good comes from yellow, and this turns out to be just as applicable in LCD screen manufacture as it was in the movie.

Liquid optically clear adhesives (LOCA) have been demonstrated to be of great value in the display assembly. They enhance and help retain optical qualities including light transmission and refraction, as well as vividness and sharpness of color and light. In this blog installment, we would like to discuss the value and use of a specific optical quality in the evaluation of LOCA materials: the b* color coordinate.

First, in Simple Terms, What Is b*?

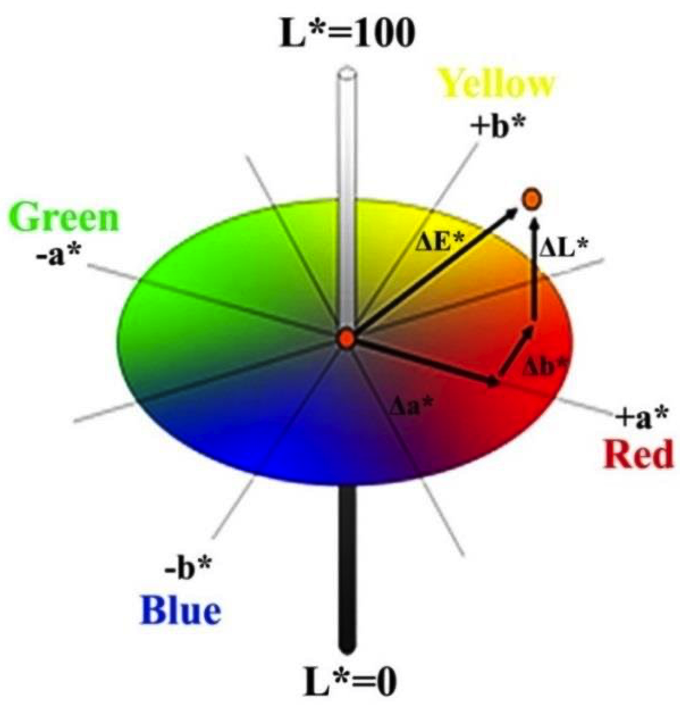

The International Commission on Illumination (CIE) in 1976 standardized a three-dimensional color space measurement approach known as CIELAB. The CIE, as mentioned just now, represents the International Commission on Illumination. LAB stands for the three axes of the color space. A visual representation of this LAB space is shown below.

Using the above-noted standard, any color and brightness can be defined within the three-dimensional space with an L* number (white/black), an a* number (red/green), and a b* number (yellow/blue). In this instance, our main concern is going to be the b* value, which in simple terms can be considered as to how “blue” or “yellow” a particular color may be. The higher the number, the more yellow. The lower (negative) the number, the bluer.

Why Is b* Number Important for LCD Displays?

There are many things that a LOCA adhesive is asked to do. First and most important, it must be an effective adhesive between the device layers or alternatively an effective sealant if it is an edge bonding material. The second critical role for LOCA is an enhancement of visual properties. To accomplish this, the adhesive must be totally clear and defect-free to allow maximum light and color transmission. This includes being free of any bubbles and free from contaminants that could cause haze. It must also be carefully designed and tuned to transmit light without distortion or diffraction to allow true image transmission.

The above-mentioned optical properties are of course the basic requirements of LOCA adhesives. The next challenge is to be certain that these optical qualities will be retained and consistent over time under real-world operating conditions. It is in this regard that b* number becomes a useful tool. The b* number is especially important in its consistency over time as yellowing of screens is considered highly undesirable and indicative of aging or failure in the eyes of consumers.

The important thing to understand is that it is not the ABSOLUTE b* value that matters, but the stability of the b* value over time and under adverse conditions.

What Types of Tests and Conditions Affect b* Stability?

Many environmental conditions have been shown in the past to lead to a yellowing of LOCA materials over time and a corresponding deterioration in image quality. By measuring the CIELAB coordinates of a given device after initial manufacture, it is then possible to expose the device to harsh conditions and measure any changes in CIELAB numbers.

In the design of LOCA materials, our scientists at Chase Corporation have developed a protocol that consists of many different tests and conditions to evaluate b* consistency. The following are some of the primary test methods and conditions utilized.

- Q-Sun Analysis

- (accelerated UV, temperature, and humidity aging test)

- Thermal Cycling/Shock Analysis

- (-60C to 125C multiple cycles, typical in automotive devices)

- Mechanical Shock Analysis

- (less common, drop tests and vibration tests for extended hours)

- Liquid and Chemical Resistance Testing

Each of these tests and all of them combined is designed to simulate years of real-world aging in environments such as in automobiles and appliances. By showing consistency over time under these conditions of the b* value, manufacturers can be confident of resistance to yellowing for LCD displays. In addition, customized testing is not uncommon in cases where a product may be exposed to unique or especially harsh conditions.

Chase Corporation, Westwood, Ma., founded in 1946, is a leading manufacturer of industrial products for high-reliability applications with a global customer base operating in diverse market sectors. Our HumiSeal® group specializes in the manufacture of polymers for the protection of PCBs. In addition, the HumiSeal group produces the Vivid Cure line of LOCA adhesives for LCD display manufacture. Our outstanding manufacturing and technical support groups can provide your organization with a reliable global supply, unmatched quality, and superior technical support.