Liquid optically clear adhesives (LOCA) provide superior optical enhancement and anti-glare properties in the manufacture of liquid crystal displays. Light, temperature and moisture can significantly affect the physical and optical properties of these adhesives, promoting yellowing or discoloration, delamination, and loss of adhesion. In this discussion, we will explain the use of “accelerated weathering exposure” in the design of LOCA and its advantages over more traditional individual factor analysis.

Liquid optically clear adhesives (LOCA) provide superior optical enhancement and anti-glare properties in the manufacture of liquid crystal displays. Light, temperature and moisture can significantly affect the physical and optical properties of these adhesives, promoting yellowing or discoloration, delamination, and loss of adhesion. In this discussion, we will explain the use of “accelerated weathering exposure” in the design of LOCA and its advantages over more traditional individual factor analysis.

Individual vs. Multi-Exposure Approaches

Individual test chambers such as thermal shock chambers, humidity-controlled chambers, and xenon arc chambers can be used to understand the effects of these exposures on adhesives’ stability. While these standard test methods can be useful, they cannot account for the synergistic effects of real-world conditions where the combination of multiple environmental challenges has been shown to be far more damaging than individual factors alone. The use of “accelerated weathering chamber (Q-Sun)” analysis allows designers to study the additive and often synergistic effect of sunlight exposure, humidity, high temperature and thermal shock. The “accelerated weathering chamber” permits customization of specific wavelength spectra and controlled temperature and humidity conditions based on product specifications and intended use. Through the use of this analysis during the product development stage, LOCA can be customized for specific optical and physical properties suitable for certain applications.

Appropriate Radiation Exposure

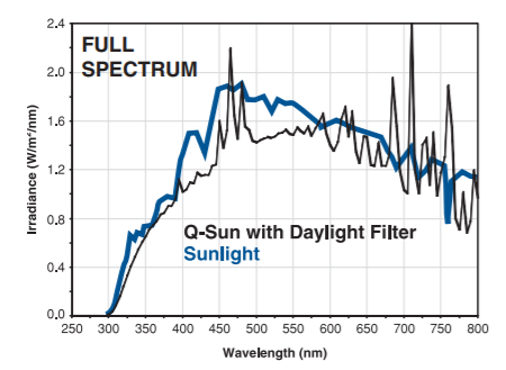

The Q-sun analyzer, also called a Xenon arc lamp chamber, can replicate the full sunlight spectrum including ultraviolet, visible, and infrared. It is also possible, through the use of optical filters, to narrowly define exposure wavelength based on adhesive chemistry and field application.

The value of the ability to filter and customize light wavelengths is obvious. As an example, in the case of a television or home computer display, it would be appropriate to select a filter replicating the indoor visible light spectrum. For automotive displays, a more suitable spectrum to simulate real world conditions would utilize the whole sunlight spectrum. Accelerated weathering analyzer approach allows for exposure to the most appropriate spectrum to simulate real-world conditions.

Graph: Full spectrum of Q-sun xenon arc lamp with daylight filter - Courtesy of q-Lab.com

Graph: Full spectrum of Q-sun xenon arc lamp with daylight filter - Courtesy of q-Lab.com

Note: An important factor to consider while using a Q-sun chamber is the age of the xenon arc lamp, since they are not as spectrally stable as florescent lamps used in QUV chambers. The spectral output of the xenon lamps may change with age; therefore, it is very important to make sure that lamps are frequently replaced.

Temperature Exposure

Along with the ability to customize light frequencies, the Q-sun analyzer further allows controlled temperature conditions in the chamber. As has been mentioned, the ability to combine both temperature and light exposure in one test process is vital to failure analysis of LOCA, since it has been shown that light and heat combined are more damaging than either of them individually. In addition, in most display and electronics applications it is almost certain that both light and heat will be present together. With Q-sun chambers, realistic light exposure conditions can be replicated while also having leverage to control temperature. The advantage of controlled temperature conditions allows one to select conditions based on adhesive chemistry and display design.

Humidity Exposure

The third and final condition that can be replicated by Q-sun analysis is exposure to various levels of humidity. To replicate environmental humidity or liquid exposure conditions, humidity is created through the use of water spray or controlled relative humidity conditions. As a result, the Q-sun chamber provides the most realistic conditions possible through the simultaneous exposure to controlled light, temperature, and humidity. An additional advantage is that the combination of light, humidity, and temperature can simulate thermal shock conditions, which often cause expansion and contraction that can lead to failures. An example of where all three exposure conditions are key is within agricultural displays where a combination of water spray and light can effectively simulate exposure conditions.

HumiSeal’s liquid optically clear adhesives have been tested as per ASTM G155, using daylight Q-filters correlating very closely with direct sunlight, along with high temperature and high humidity exposure. HumiSeal LOCA do not show any signs of discoloration, shrinkage, or reversion after these extreme weathering conditions, making it suitable for applications in displays used in automotive, aerospace, military, marine, and medical devices.

As a supplier of electronics protection polymers and coatings, Chase Corporation and our employees can help you with an unbiased approach to evaluating your application and process. We’ll show you how to maximize efficiency, minimize cost, and improve product reliability. Our outstanding manufacturing and technical support groups can provide your organization with reliable global supply, unmatched quality, and superior technical support.