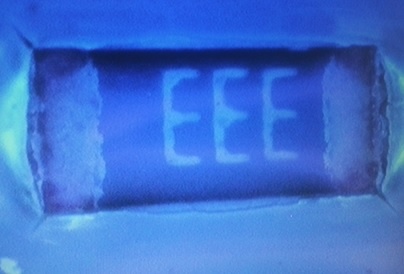

Figure 1: Thermally induced cracking in conformal coating

Does your conformal coating require long term thermal shock testing? Do you struggle to overcome cracking and adhesion loss with your current conformal coating after 1000 thermal shock cycles? With the drive for increasing functionality for end devices, and increased life cycles being placed on all electronic assemblies, the need to have materials endure more stringent testing becomes increasingly vital. Necessary robustness to these stringent conditions force suppliers like HumiSeal to innovate new material solutions to address these requirements.