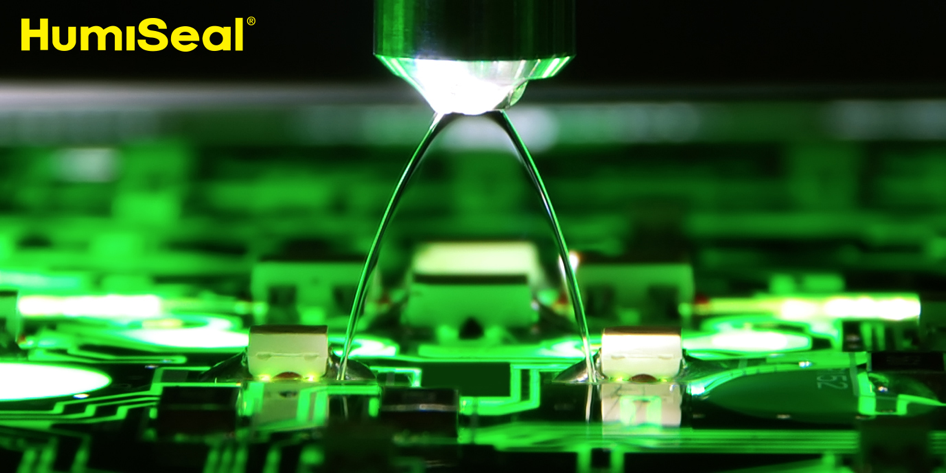

Take a quick look at the photograph on your right. If you are in the business of PCB manufacturing with conformal coatings, does it frighten or concern you at all? Does the magnified coating appear to truly “conform” to the surfaces evenly? And if not, what effect, if any, might this have on the protection of your PCBs?

First of all, don’t panic. What you see in the photograph is not unusual and is not necessarily a problem. It is important, however, that if you are in the business of applying conformal coatings, you should have a clear understanding of some of the unique challenges they present.