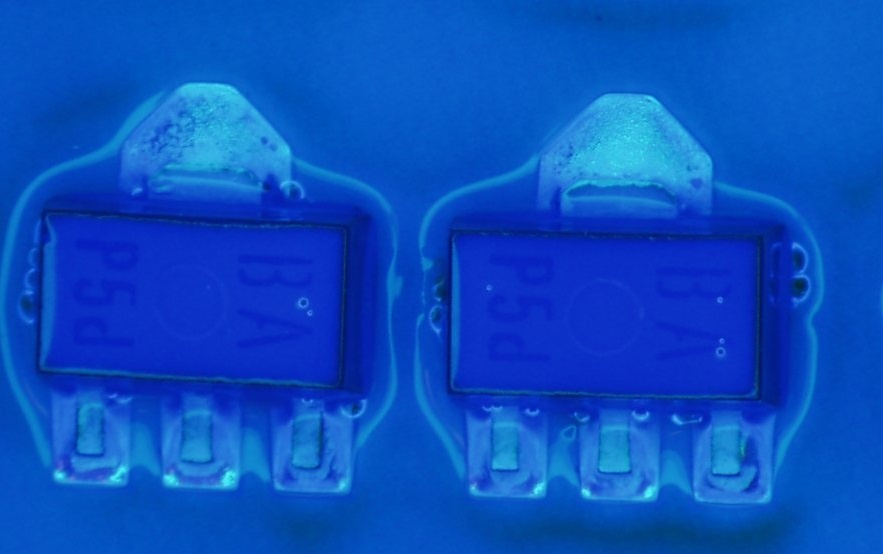

The conformal coating process, like any other processes, has different variables, inputs, and outputs. In order to be able to control the results of your application (outputs), we need to fully understand how each variable affects the process.

The importance of the variables

To get the right amount of liquid, thickness, right coverage, no contamination on keep out areas, etc., you need to identify and understand the variables of the process.

The most important variables:

- Viscosity

- Flow

- Machine parameters (speed and Height)

- Curing method

In this blog, we will concentrate on reviewing the first variable: Viscosity